Process mining

What is process mining?

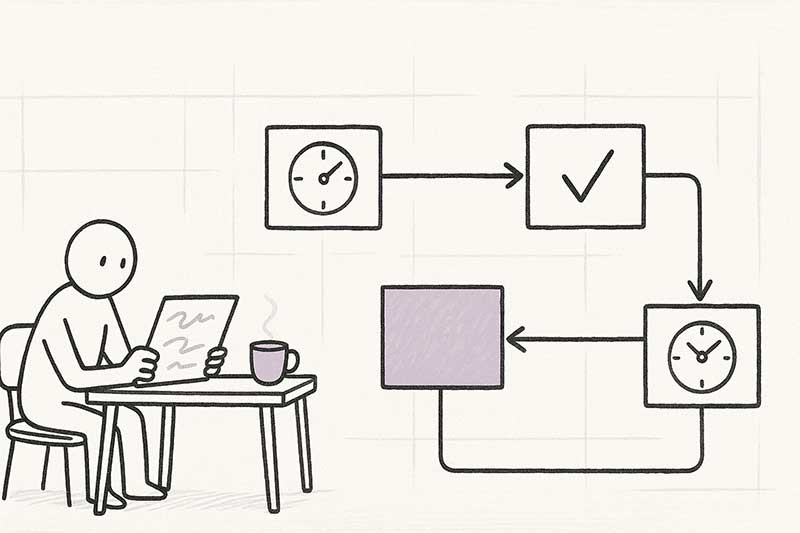

Process mining is a way to see how your business really runs, not just how you think it runs. Every time people use systems like ERP, CRM, or HR software, those systems keep digital traces of what happens. When an order is created, approved, shipped, and paid, all of that is stored as data.

Process mining takes those traces and turns them into a clear picture of your actual processes. It shows where things move smoothly, where they slow down, and where people skip steps or take detours.

You can think of it as a GPS for your business processes. It lets you follow the real route every order, invoice, or request takes from start to finish. Sometimes you’ll find surprises, like approvals that take too long or steps that are repeated without reason.

Once you see how work truly flows, you can fix what’s not working. That’s the real value of process mining. It helps teams make better decisions based on facts, not assumptions.

In short, process mining turns data into insight, helping you understand, measure, and improve how your business operates every day.

When do companies use process mining?

Companies use process mining when they want to understand how work really happens inside their systems and identify where things can be improved. Common moments include:

Before a process improvement project

To get a clear, fact-based picture of the current process before making changes.During digital transformation

To make sure new tools or automation fit how the business actually operates, not just how it’s documented.When performance drops

To find the root cause of longer lead times, rising costs, or missed deadlines.For compliance or audit checks

To verify if people follow rules and approval flows as intended.After mergers or system changes

To compare processes between business units or see how new systems affect workflows.To identify automation opportunities

To pinpoint repetitive manual steps that can be automated.

Companies use process mining when they want to move from guessing to knowing. It helps them base decisions on data rather than assumptions.

What are common use cases of process mining?

Common use cases of process mining include:

Order-to-cash

Tracking how customer orders move from purchase to payment. It helps spot delays in approvals, invoicing, or shipping.Purchase-to-pay

Following how supplier invoices are handled, from order creation to payment. Useful for finding duplicate payments or bottlenecks in approval chains.Customer service

Analyzing ticket handling times and identifying where cases get stuck or passed between teams too often.Finance and accounting

Checking how journal entries, reconciliations, or month-end closings actually happen. It helps uncover inefficiencies and control gaps.Compliance and audit

Verifying that business processes follow internal rules or regulations. For example, checking that no one approves their own purchase orders.Production and logistics

Finding delays in production lines or delivery routes by comparing planned versus actual process flows.IT and incident management

Understanding how support tickets are resolved and where process automation can reduce manual work.

Process mining is used anywhere there’s a process with digital footprints. It helps improve speed, reduce waste, and strengthen control.

What data do you need to use process mining?

To use process mining, you need data that shows how each step in a process happens over time. This comes from the systems people use every day, such as ERP, CRM, HR, or ticketing tools.

The core data is called an event log, and it always includes three key parts:

Case ID – a unique identifier for each process instance, like an order number, invoice number, or ticket ID.

Activity name – the action that was taken, such as “order created,” “invoice approved,” or “payment made.”

Timestamp – the exact date and time when each activity happened.

Extra fields make the analysis more powerful, such as:

Who performed the action (user or role)

How long each step took

Department, system, or country

Amounts or values linked to the process

With these elements, process mining tools can rebuild the full story of how work flows from start to finish. The more complete and accurate the data, the clearer the insights. Creating an event log is by far the biggest challenge in process mining. It often requires you to combine data from various sources and systems.

Related Terms

Data Warehouse

A data warehouse is a central system that collects and organises data from diffe...

Event log

An event log is the foundation of process mining. It records every step that hap...

Microsoft Fabric

Microsoft Fabric is an all-in-one cloud platform that brings data storage, trans...

OneLake

OneLake is Microsoft’s central data storage system within Microsoft Fabric. It s...

Power Bi

Power BI is Microsoft’s business intelligence tool that helps people understand ...

Version control for Power BI

Simple guide to set up version control for Power BI using PBIP, Git and clean repo structures. Learn...

Nov 20, 2025

How to create an event log for process mining

A step by step guide on how you can create an event log for process mining.

Nov 18, 2025